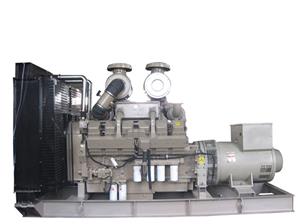

C Series 825 kVA DG Set 50Hz

- Bidirection Power

- Cummins China

- 30 - 45 days

- 1000 sets

C Series 825 kVA DG Set 50Hz is powered by Cummins diesel engine KTA38-G2 which has many features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields. Cummins serves customers with International Warranty Services (IWS).How to effectively solve the noise of the engine generator set?

Generally speaking, the normal noise of the diesel engine generator set is between 98-112dB(A). This noise is relatively large, and noise reduction is not required in general production places. However, for densely populated urban residential areas, high-end office buildings, star hotels, For scientific research institutions, hospitals, and colleges and universities, the general noise limit is 70-75dB(A), and noise reduction processing is required. There are generally two ways to reduce noise, one is to reduce noise in the computer room, and the second is to make a low-noise cabinet. The following power genset exchange will tell you how we effectively solve the noise of dg set for the type C Series 825 kVA DG Set 50Hz.

Generally speaking, there are two methods to solve the noise of the engine genset. The first is to make a low-noise box-type power genset station, and the second is to reduce noise in the computer room.

1. Low-noise box-type power genset station

The low-noise box-type power station is suitable for places with high noise reduction requirements. The low-noise power genset station adopts scientific and perfect measures such as vibration isolation, noise reduction, sound insulation, and sound absorption, so that its noise index is greatly reduced, and the noise reduction range is more than 30dBA. The power of the product covers 50KW-600KW, up to twelve varieties. Its characteristics are as follows:

1. Vibration isolation facilities, high-performance shock absorbers are used between the diesel engine generator set and the bridge to reduce noise sources;

2. The sound insulation cover, which is made of four to five layers of sound-absorbing materials, is sound-absorbing and sound-insulating, and has powerful functions;

3. The air inlet muffler, the labyrinth-type air inlet muffler with three layers of sound-absorbing materials, can ensure sufficient air inflow and ensure that the noise does not spread;

4. The exhaust muffler, the labyrinth-type exhaust muffler with three layers of sound-absorbing materials, not only ensures the unobstructed exhaust, but also ensures that the noise does not spread;

5. The use of proprietary muffler and impedance compound muffler greatly reduces the noise reduction when exhaust gas is discharged;

6. The power cable connection adopts a fixed junction box structure, which is directly connected outside the box.

In addition, the structure of the sound insulation cover is similar to that of the sound insulation cover. The windows are double-glazed, and the doors and windows and the sound insulation cover are strictly sealed to prevent noise from leaking through the doors and windows.

2. Noise reduction in the computer room

(1) Methods of reducing noise and the noise reduction measures adopted

At present, the methods of reducing noise at home and abroad include sound insulation, sound absorption, sound absorption, damping, vibration reduction, etc. The noise reduction project of the computer room adopted by Bidirection Power adopts all the above measures, and the operating noise of its units meets the requirements of environmental protection.

(2) Measures and main materials used to reduce noise

The sound absorption part of the noise reduction of the computer room is generally 240mm thick brick walls and a flat roof of cement floor. In order to reduce the noise in the computer room, sound absorption treatment is required on the inner wall of the computer room and the inner wall of the roof, as follows:

1. Around the wall: Use U-shaped dragon frame, sound-absorbing cotton, glass cloth, perforated sound-absorbing board (thickness not less than 0.6mm), etc. to cover a layer of 100-120mm sound-absorbing wall around the wall.

2. The inner wall of the roof: U-shaped dragon frame, sound-absorbing cotton, glass cloth, perforated sound-absorbing aluminum plate (thickness not less than 0.6mm), etc., are used to hang a 120-150mm sound-absorbing layer under the roof. It can reduce the noise in the computer room by 10-15DBA.

3. The sound insulation part of the computer room: In order to prevent the noise in the computer room from being transmitted, the door of the computer room must be sealed for sound absorption and sound insulation. Generally, the average noise reduction of a single-layer door is TL=15-20DBA, The average noise reduction of double doors is TL=25-35DBA, and the average noise reduction of special double doors can reach TL=35-45DBA. Special sound insulation doors are specially designed, manufactured and installed according to the noise characteristics of generator sets. Moreover, the door and the door frame are sealed.

4. Shock absorption of the engine generator set: The base frame of the dg set and the ground foundation do not use the traditional anchor bolt rigid connection, but use the special rubber spring shock absorber for the high-performance diesel engine generator set, which can reduce the noise by 5-10DBA.

5. Internal ventilation of the engine room: The ventilation of the engine genset room is the key to the success of the noise reduction and noise reduction project in the engine room, and it is also a prerequisite for the normal operation of the dg set. While meeting the noise reduction effect, the ventilation requirements of the generator set for the machine room must be considered. Since the dg genset set requires a lot of fresh air during operation, the exhaust and exhaust ducts of the machine room must be designed to meet the requirements. A lot of noise is also from the air inlet. The ducts and exhaust ducts are spread outside the machine room. Reasonable design of the air inlet and exhaust ducts is an important part of reducing noise. The air inlet and exhaust ducts of the engine generator set are made of brick-folded ducts, and a special air inlet muffler and exhaust muffler are installed. The inner cavity is equipped with sound-absorbing materials. And perforated sound-absorbing panels. At the same time, in order to ensure that the unit can operate at rated power for a long time, the air inlet and outlet of the unit must reserve enough exhaust area according to the requirements of the unit. The exhaust duct of the unit should be equipped with a low-noise axial fan In order to ensure sufficient ventilation in the computer room, the noise reduction is expected to be 25-30DBA through the above methods.

Exhaust noise is the main noise source of the unit. The use of two mufflers in series for secondary noise reduction is expected to reduce TL=30-40DBA. On the other hand, the exhaust pipe connection must have good sealing performance, and part of the noise is exhausted through the exhaust pipe. To the atmosphere.

The following C Series 825 kVA DG Set 50Hz specification for reference once you buy.

| C Series 825 kVA DG Set 50Hz Specification | |||

| Generator Model | BP-C825 | Engine Model | Cummins KTA38-G2 (CCEC) |

| Standby Power | 825kVA/660kW | Prime Power | 750kVA/600kW |

| Frequency | 50Hz | Rotational Speed | 1500rpm |

Engine Specification for C Series 825 kVA DG Set 50Hz | |||

| Governor | Electronic | Weight | 3880KG |

| No. of Cylinders | 12 | Aspiration | Turbocharged and Aftercooled |

| Displacement | 37.8L | Fuel System | Direct Injection Cummins PT |

Hourly Fuel Consumption (100% Output Power) | 167L | Total System Oil Capacity | 135L |

| Power Range | 664-731kW | Horse Power Range | 890-980 |

Cummins KTA38 series engines are all with features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields. As a leading manufacturer of power equipment, Cummins serves customers with International Warranty Services (IWS) in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor locations and approximately 7,400 dealer locations.

Battery & charger: with 4 maintenance free batteries (200AH) and one DC battery charger (24V), to support genset with reliable starting power supply;

Dimension: 4410mm*1720mm*2170mm (Open type); 6050mm*2430mm*2580mm (20FT Containerized type)

Weight: 7190 kg (Open type); 10100 kg (20FT Containerized type)

In order to prevent the temperature of the diesel engine generator room from rising after the unit has been running for a long time, which will affect the output power genset of the unit, the exhaust gas exhaust pipe and the exhaust muffler of the unit are insulated and kept warm. In order to ensure that the equipment room meets the fire protection requirements, the lighting of the equipment room shall be installed in accordance with the fire protection requirements. After the above-mentioned methods of silencing, sound insulation, and sound absorption, the noise at 1M outside the computer room can be no more than 65DBA.

There are many types of generator sets, and there are different types of generator sets according to different standards. 1. Divided by power source: diesel generator sets, gas generator sets, gasoline generator sets, wind generator sets, solar generator sets, hydroelectric generator sets, coal-fired generator sets, etc. 2. Electric energy mode: According to the converted electric energy mode, i...more