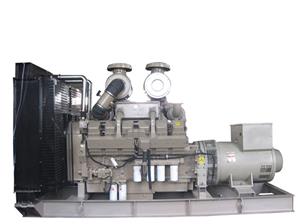

C Series 1650 kVA DG Set 50Hz

- Bidirection Power

- Cummins China

- 30 - 45 days

- 1000 sets

C Series 1650 kVA DG Set 50Hz is powered by Cummins diesel engine KTA50-GS8 which has many features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields. Cummins serves customers with International Warranty Services (IWS).How many diesel engine generator sets are most suitable

We all know that we generally need to purchase diesel engine generator sets when we need to supply power for a long time or when backup power is needed, and many customers also have a better understanding of its technical parameters, but you know how many diesel generator sets should be purchased. Is it appropriate? Today,Bidirection Power Technology is here to answer everyone's questions.

Under normal circumstances, the number of commonly used dg diesel generator sets is usually set to 2 or more to ensure the continuity of power supply and adapt to changes in the diesel generator power load curve. When the number of units is large, the number of units to be put into the generating unit can be determined according to the change of the electric load, so that the diesel engine is often operated under economic load to reduce fuel consumption rate and whole house backup generator cost.

The best economic operation state of diesel engine is between 75%-90% of the rated power. In order to ensure the continuity of power supply, the common unit itself should consider setting up a standby unit, so that the generator unit can still supply uninterrupted and continuous power supply for important electrical loads when the unit is repaired or shut down for inspection.

It can be said that once it is necessary to purchase diesel generator sets, under normal circumstances, it should be equipped with more than two sets. This is to ensure the continuity of power supply. Of course, comprehensive factors such as cost and time must be considered. Interoperability of electricity is used as a professional diesel generator. Generator set manufacturers, we will provide you with a professional design plan, choose the most suitable diesel generator set configuration plan, welcome to consult.

You need to pay attention to the following points when buying a dg diesel generator set

1 Pay attention to the following aspects when purchasing diesel generator sets:

You must first determine how much power the unit to choose. The diesel engine power should be more than 30% greater than the selected power, and the motor power should be reserved by 10%. If there is a high-power single motor (non-frequency conversion start), the diesel engine power needs to be greater than the motor power of times can start the motor smoothly;

2 It is necessary to choose which brand price of diesel engine and generator to choose. For diesel engine, consider the configuration with mature technology, low fuel consumption, low maintenance cost, low maintenance cost and high reliability. The generator chooses domestic manufacturers that produce brushless motors in regular batches. The quality can meet the requirements;

3 The selection of the unit control unit should consider the place used by the user. For example, the rental industry or the unit whose operators are not accustomed to using LCD screens can choose to use manual screens, and where automation requirements are high, full LCD screens can be used;

4 When buying, you should also prevent bad manufacturers from cheating on the power of generators and diesel engines, and ask whether the cooling water tank and generator are made of pure copper in the unit configuration!

a. First calculate the total power of the generators you bring, the unit power must be greater than 30% of the total

b. If the load has a motor (non-frequency conversion start), three times its power can be started normally.

c, choose a big brand, after-sales guarantee!

d. Whether the motor is copper wire or aluminum wire, national standard or non-standard.

2. Principle of diesel generator

The basic structure of diesel power generation is composed of a diesel engine and a generator. The diesel engine is used as the power to drive the generator to generate electricity.

Let me talk about the basic structure of a diesel engine: it is composed of cylinders, pistons, cylinder heads, intake valves, exhaust valves, piston pins, connecting rods, crankshafts, bearings and flywheels. The diesel engine of the diesel generator is generally a single-cylinder or multi-cylinder four-stroke diesel engine. The following only talks about the basic working principle of a single-cylinder four-stroke diesel engine: the start of a diesel engine is to turn the crankshaft of the diesel engine by manpower or other power to make the piston work in the top closed cylinder. Repeated movement up and down. The piston completes four strokes in motion: intake stroke, compression stroke, combustion and power (expansion) stroke, and exhaust stroke. When the piston moves from top to bottom, the intake valve opens. The fresh air filtered by the air filter enters the cylinder to complete the intake stroke. The piston moves from bottom to top, the intake and exhaust valves are closed, the air is compressed, the temperature and pressure increase, and the compression process is completed.

When the piston is about to reach its apex, the fuel injector sprays the filtered fuel into the combustion chamber in an atomized state and mixes with high-temperature and high-pressure air to immediately ignite and burn. The resulting high pressure pushes the piston down to work and pushes the crankshaft to rotate. Complete the work schedule. After the work stroke is completed, the piston moves from bottom to top, the exhaust valve opens to exhaust, and the exhaust stroke is completed. The crankshaft rotates half a turn per stroke. After several working cycles, the diesel engine gradually accelerates into work under the inertia of the flywheel.

The rotation of the crankshaft of the diesel engine drives the generator to rotate and generate electricity. There are DC generators and AC generators:

The DC generator is mainly composed of generator shell, magnetic pole core, magnetic field coil, armature and carbon brush. Working principle of power generation: When the diesel engine drives the generator armature to rotate, because the magnetic pole core of the generator has remanent magnetism, the armature coil cuts the magnetic lines of force in the magnetic field. According to the principle of electromagnetic induction, the current is generated by magnetic induction and output through the carbon brush. .

The alternator is mainly composed of a number of permanent magnets (called a rotor) with alternating north and south poles made of magnetic materials and an armature coil (called a stator) made of silicon cast iron and wound with multiple sets of serial coils. Working principle of power generation: The rotor is driven by the diesel engine to cut the magnetic lines of force in the axial direction. The alternating magnetic poles in the stator form an alternating magnetic field in the coil core. The rotor rotates once, and the direction and size of the magnetic flux are changed many times. Due to the changing effect of the magnetic field, In the coil, an induced current of varying size and direction is generated and the current is delivered by the stator coil. In order to protect the electrical equipment and maintain its normal operation, the current generated by the generator also needs a regulator for adjustment control and so on. 8 traps that users should pay attention to when buying diesel generator sets:

1. Confusing the relationship between KVA and KW. Treat KVA as KW exaggerated power and sell it to customers. In fact, KVA is the apparent power, and KW is the effective power. The relationship between them is 1KVA=0.8KW. Imported units are generally expressed in KVA, while domestic electrical equipment is generally expressed in KW. Therefore, when calculating power, KVA should be discounted to KW.

2. Don't talk about the relationship between long-travel (rated) power and backup power, just talk about a "power" and sell the backup power as long-travel power to customers. In fact, the reserve power = 1.1 × long-travel power. Moreover, the backup power can only be used for 1 hour during 12 hours of continuous operation.

3. The power of the diesel engine is the same as that of the generator in order to reduce the cost. In fact, the industry generally stipulates that diesel engine power ≥ 10% of generator power because of mechanical loss. Worse still, some people misreport the horsepower of the diesel engine as kilowatts to the user, and use a diesel engine that is less than the power of the generator to configure the unit, commonly known as a small horse-drawn cart, and the service life of the unit is reduced. Frequent maintenance and high usage costs.

4.Sell second-hand refurbished machines as brand-new machines to customers, and some refurbished diesel engines are equipped with brand-new generators and control cabinets, so that ordinary non-professional users cannot tell whether they are new or old.

5.Only report the brand of diesel engine or generator, not the place of production, and the brand of the unit. Such as Cummins bakcup generator in the United States, volvo diesel generator(Volvo) in Sweden, and Stamford in the United Kingdom. In fact, no diesel generator set can be completed by a single company. Customers should fully understand the manufacturer and brand of the diesel engine, generator, and control cabinet of the unit in order to comprehensively evaluate the grade of the unit.

6.Sell the unit without protection function (commonly known as four protection) as a unit with complete protection functions to customers. What's more, the unit with incomplete instrumentation and no air switch is sold to customers. In fact, the industry generally stipulates that units above 10KW must be equipped with full meters (commonly known as five meters) and air switches; large-scale units and automatic units must have self-four protection functions.

7.Don't talk about the brand grade of diesel engine and generator, control system configuration, don't talk about after-sales service, just talk about price and delivery date. Some also use non-power station special oil engines, such as marine diesel engines and automotive diesel engines for generating sets. The quality (voltage and frequency) of the terminal product of the unit cannot be guaranteed. Units with too low prices generally have problems, commonly known as: There is no mistake when you buy it wrong!

8.Don't talk about the random accessories, such as with or without silencer, fuel tank, oil pipeline, what grade battery, how big capacity battery, how many batteries, etc. In fact, these attachments are very important and must be stated in the contract. What's more, even the water tank fan is not included, allowing customers to open the pool by themselves. Diesel generator sets are important backup power equipment, so you need to be cautious when purchasing them, and use them with ease.

| C Series 1650 kVA DG Set 50Hz Specification | |||

| Generator Model | BP-C1650 | Engine Model | Cummins KTA50-GS8 (CCEC) |

| Standby Power | 1650kVA/1320kW | Prime Power | 1500kVA/1200kW |

| Frequency | 50Hz | Rotational Speed | 1500rpm |

Engine Specification for C Series 1650 kVA DG Set 50Hz | |||

| Governor | Electronic | Weight | 5360KG |

| No. of Cylinders | 16 | Aspiration | Turbocharged & Low Temperature Aftercooled |

| Displacement | 50.3L | Fuel System | Direct Injection Cummins PT |

Hourly Fuel Consumption (100% Output Power) | 309L | Total System Oil Capacity | 204L |

| Power Range | 1287-1429kW | Horse Power Range | 1725-1915 |

Cummins KTA50 series engines are all with features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields.

Dimension: 4960mm*2200mm*2620mm (Open type); 12192mm*2438mm*2896mm (40HQ Containerized type)

Weight: 10370 kg (Open type); 22500 kg (40HQ Containerized type)

Checking the above C Series 1650 kVA DG Set, you will know how many genset power you need in different application.

There are many types of generator sets, and there are different types of generator sets according to different standards. 1. Divided by power source: diesel generator sets, gas generator sets, gasoline generator sets, wind generator sets, solar generator sets, hydroelectric generator sets, coal-fired generator sets, etc. 2. Electric energy mode: According to the converted electric energy mode, i...more