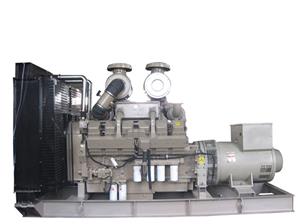

C Series 1375 kVA DG Set 50Hz

- Bidirection Power

- Cummins China

- 30 - 45 days

- 1000 sets

C Series 1375 kVA DG Set 50Hz is powered by Cummins diesel engine KTA50-G3 which has many features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields. Cummins serves customers with International Warranty Services (IWS).Preparation work for diesel engine generator set test.

Preparation work for diesel engine generator set test

◎The inspection steps before the diesel engine test are as follows:

1) Check whether the surface of the engine generator set is clean; whether the anchor nuts, flywheel screws and other moving parts are loose, and if any problems are found, tighten them in time;

2) Check whether the gaps of each part are correct, and in particular, carefully check whether the gaps between the intake and exhaust valves and the pressure relief mechanism meet the requirements.

3) Put each cylinder in the decompression position, rotate the crankshaft to check whether there is any abnormal noise in the operation of each cylinder, and whether the crankshaft rotates freely, and pump the oil into a friction surface at the same time, then close the decompression mechanism and shake the crankshaft, Check whether the cylinder is leaking. If it feels hard to shake the crankshaft, it means that the compression is normal.

4) Check the condition of the fuel supply system, the steps are as follows:

Check whether the vent hole on the fuel tank cap is smooth. If there is dirt in the hole, clean it up. Whether the diesel oil meets the requirements, whether the fuel quantity is sufficient, and turn on the oil circuit switch. Turn on the decompression mechanism and crank the crankshaft. Each cylinder should have a crisp sound of fuel injection, indicating good fuel injection. If you hear the sound of fuel injection but no oil, there may be air in the oil circuit. At this time, loosen the diesel filter and the bleed screw of the fuel injection pump to remove the air from the oil circuit. Check the oil pipes and joints for oil leakage, and deal with the problems in time.

5) Check the condition of the water cooling system, the steps are as follows:

Check whether the amount of cooling water in the water tank is sufficient. If the amount of water is insufficient, add enough clean and soft water. Check whether there is water leakage in the joint water pipe, and deal with and solve the problem in time. Check whether the impeller of the cooling water pump rotates flexibly and whether the transmission belt is tight. Check the tightness of the transmission belt, push it by hand in the middle of the rotating belt, and the transmission belt should be pressed down by 10~15mm.

6) Check the condition of the lubrication system, the steps are as follows:

Check the oil pipes and pipe joints for oil leakage, and solve the problems in time. Check the amount of oil in the oil pan, pull out the dipstick next to the crankcase, and observe whether the height of the oil level meets the regulatory requirements. Otherwise, add oil. For diesel engine generator set, add No. 8 or No. 11 diesel engine oil in winter and 14 in summer. No. engine oil. During the inspection, if the oil level is found to be above the regular height, the reasons for the increase in oil should be carefully analyzed. There are usually three reasons:

a. When adding engine oil, add too much.

b. Diesel fuel leaks into the crankcase, diluting the engine oil.

c. Cooling water leaks into the engine oil.

③ If you need to manually refuel the oil holes, you should add dg oil as a grease gun.

7) Check the starting system, the steps are as follows:

①Use point to start diesel engine generator set, the steps are

a. Check whether the electro-hydraulic proportion of the starting battery is within the range of 1.240~1.280. If the proportion is less than 1.180, it indicates that the battery is insufficient.

b. Check whether the power cord is correct.

c. Check whether there is dirt or oxidation on the battery terminal, which should be polished clean.

d. Check whether the electric shock contact of the starter motor and electromagnetic operating mechanism is good.

According to C series 1375 kVA sepcification, you need to do preparation work for diesel engine generator set test.

| C Series 1375 kVA DG Set 50Hz Specification | |||

| Generator Model | BP-C1375 | Engine Model | Cummins KTA50-G3 (CCEC) |

| Standby Power | 1375kVA/1100kW | Prime Power | 1250kVA/1000kW |

| Frequency | 50Hz | Rotational Speed | 1500rpm |

Engine Specification for C Series 1375 kVA DG Set 50Hz | |||

| Governor | Electronic | Weight | 5360KG |

| No. of Cylinders | 16 | Aspiration | Turbocharged & Aftercooled |

| Displacement | 50.3L | Fuel System | Direct Injection Cummins PT |

Hourly Fuel Consumption (100% Output Power) | 274L | Total System Oil Capacity | 177L |

| Power Range | 1150-1227kW | Horse Power Range | 1541-1645 |

Cummins KTA50 series engines are all with features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields.

Dimension: 5000mm*2080mm*2290mm (Open type); 12192mm*2438mm*2896mm (40HQ Containerized type)

Weight: 9280 kg (Open type); 22100 kg (40HQ Containerized type)

There are many types of generator sets, and there are different types of generator sets according to different standards. 1. Divided by power source: diesel generator sets, gas generator sets, gasoline generator sets, wind generator sets, solar generator sets, hydroelectric generator sets, coal-fired generator sets, etc. 2. Electric energy mode: According to the converted electric energy mode, i...more