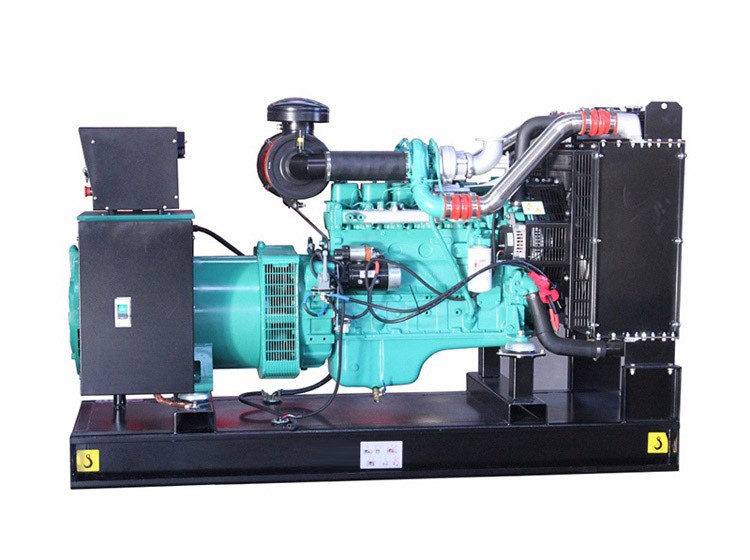

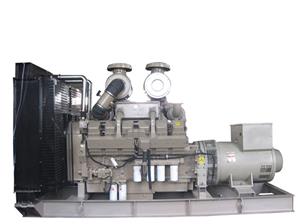

C Series 138 kVA DG Set 50Hz

- Bidirection Power

- Cummins China

- 30 - 45 days

- 1000 sets

C Series 138 kVA DG Set 50Hz is powered by Cummins diesel engine 6BTAA5.9-G2 which has many features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the small or medium power (prime or standby) demand on residential use, small shops, small projects and other fields. Cummins serves customers with International Warranty Services (IWS). And the common problems of parallel diesel engine generator sets.

Common problems of parallel diesel engine generator sets

Common problems of parallel diesel engine generator sets one. What are the conditions for parallel operation of dg set?

The whole process of putting dg genset into parallel operation is called paralleling. Run one generator set first and send the voltage to the bus bar. After the other generator set starts, it will be parallel with the previous dg set. At the moment of closing, the dg genset should not have harmful inrush current. No sudden shocks. After closing, the rotor should be pulled into synchronization quickly. (That is, the rotor speed is equal to the rated speed) Therefore, the parallel power genset must meet the following conditions:

1. The effective value and waveform of the generator set voltage must be the same.

2.The phase of the voltage of the two generators is the same.

3.The frequency of the two cummins generator sets is the same.

4. The phase sequence of the two cummins generator sets is the same.

2. What is the quasi-synchronous parallel method for generating units? How to parallelize?

Quasi-synchronous is the exact cycle. Parallel operation is performed by using the quasi-synchronization method. The engine generator set must have the same voltage, the same frequency and the same phase. This can be monitored by two voltmeters, two frequency meters, a synchronization table and a non-synchronization indicator installed on the synchronization disk. Proceed as follows:

Turn on the load switch of one of the generator sets to send the voltage to the bus bar, while the other generator set is in the standby state.

Close the beginning of the same period, adjust the speed of the generator set to be paralleled to make it equal to or close to the synchronous speed (with the frequency difference of the other generator set within half a cycle), and adjust the voltage of the generator set to be paralleled to the other The voltage of the generator set is close. When the frequency and voltage are similar, the rotation speed of the synchronization meter is getting slower and slower, and the synchronization indicator is also on and off from time to time; when the phase of the parallel unit is the same as another unit, the pointer of the synchronization meter Indicating to the upper middle position, the synchronization light is the darkest. When the phase difference between the unit to be paralleled and the other unit is the largest, the synchronization meter points to the lower center position. At this time, the synchronization light is the brightest. When the synchronization meter pointer rotates clockwise This means that the frequency of the power genset to be paralleled is higher than that of the other unit. The speed of the engine generator set to be paralleled should be reduced. On the contrary, when the pointer of the synchronization meter rotates counterclockwise, the speed of the generator to be paralleled should be increased. When the pointer of the synchronization meter rotates slowly in the clockwise direction and the pointer is close to the synchronization point, immediately close the circuit breaker of the unit to be connected to make the two generating units parallel. After paralleling, cut off the synchronization table switch and related synchronization switches.

If customers want to use C Series 138 kVA DG Set to do parallel, check the specification first.

| C Series 138 kVA DG Set 50Hz Specification | |||

| Generator Model | BP-C138 | Engine Model | Cummins 6BTAA5.9-G2 (DCEC) |

| Standby Power | 138kVA/110kW | Prime Power | 125kVA/100kW |

| Frequency | 50Hz | Rotational Speed | 1500rpm |

Engine Specification for C Series 138 kVA DG Set 50Hz | |||

| Governor | Electronic | Weight | 411KG |

| No. of Cylinders | 6 | Aspiration | Turbocharged & Charge Air Cooled |

| Displacement | 5.9L | Fuel System | BYC PB Direct Injection |

Hourly Fuel Consumption (100% Output Power) | 30L | Minimum Required Oil Capacity | 16.4L |

| Power Range | 120-130kW | Horse Power Range | 161-174 |

Cummins 6BTAA series engines are all with features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high parts commonality & long service life, providing powered diesel generator sets with great transient response, wide application, high economic efficiency & high reliability, and meeting the small or medium power (prime or standby) demand on residential use, small shops, small projects and other fields. As a leading manufacturer of power equipment, Cummins serves customers with International Warranty Services (IWS) in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor locations and approximately 7,400 dealer locations.

Alternator: Stamford, Leroy Somer, Marathon, Mecc Alte, Engga, etc. With great excitation, enable genset to bear high power transient load. Ratings: Power Factor 0.8, 3 Phase 4 Wire, H insulation & IP23;

Control System: ComAp, Deepsea, Smartgen, etc. To control gensets intelligently and support genset in stable operation;

Shortcut Protection: standard three phase Delixi MCCB. Schneider & ABB for options;

Radiator: standard 50℃ radiator, closed water cooled system, to support rated power output under strict temperature environment;

Anti-vibration Shock Absorbers: with built-in integrated anti-vibration system, easy for transportation & installation;

Fuel Tank: open type without fuel tank and silent type with built-in fuel tank (8-10 operating hours capacity);

Start Motor: DC 24V start motor;

Battery & charger: with 2 maintenance free batteries (100AH) and one DC battery charger (24V), to support genset with reliable starting power supply;

Dimension: 2400mm*950mm*1530mm (Open type); 3280*1080*1765mm (Silent type)

Weight: 1240 kg (Open type); 1810 kg (Silent type)

There are many types of generator sets, and there are different types of generator sets according to different standards. 1. Divided by power source: diesel generator sets, gas generator sets, gasoline generator sets, wind generator sets, solar generator sets, hydroelectric generator sets, coal-fired generator sets, etc. 2. Electric energy mode: According to the converted electric energy mode, i...more