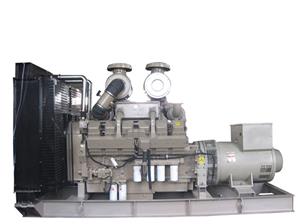

C Series 1250 kVA DG Set 50Hz

- Bidirection Power

- Cummins China

- 30 - 45 days

- 1000 sets

C Series 1250 kVA DG Set 50Hz is powered by Cummins diesel engine KTA38-G9 which has many features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields. Cummins serves customers with International Warranty Services (IWS).The installation and inspection steps of the alternator for 1250 kVA DG Set.

The installation and inspection steps of the alternator for 1250 kva generator are as follows:

1) The alternator and diesel engine generator are coupled, and the parallelism and concentricity of the coupling are required to be less than 0.05mm. In actual use, the requirement can be slightly lower, about 0.1mm or less, too large return affects the normal operation of the bearing, resulting in damage, and the coupling should be fixed with positioning pins. Before installation, retest the coupling.

2) When the sliding bearing generator is coupled, the height of the generator center should be adjusted slightly to the center of your dg set, so that the weight of the flywheel on the diesel engine will not be transferred to the generator bearing, otherwise the generator bearing will bear extra The weight of the flywheel is not conducive to the formation of the oil film of the sliding bearing, resulting in heat generation and even burning of the bearing. This type of dg genset must not carry any heavy objects on the coupling.

3) When installing the standby generators for home use, ensure that the cooling air inlet is unobstructed, and avoid exhausting hot air before entering the generator. If there are shutters on the ventilation cover, the window should face down to meet the requirements of the protection level.

4) The mechanical coupling of single-bearing generators should pay special attention to the uniform air gap between the stater and rotor.

5) According to the schematic diagram or wiring diagram, select the appropriate power cable and use copper connectors for wiring. After the copper connector and the bus bar, the bus bar and the bus bar are tightened, the local gap at the joint is not more than 0.05mm, and the distance between the wires is No more than 10mm, and the necessary grounding wire must be installed.

6) There are U, V, W, N marks on the terminal of the generator outlet box. It does not mean that the actual phase sequence depends on the direction of rotation. UVW printed on the certificate indicates the actual phase sequence when rotating clockwise, and VUW means the actual phase sequence when rotating counterclockwise.

7) If the neutral point of each generator is connected to each other in the standby power system, or the neutral point of the generator is connected to the neutral point of the transformer and its load, the diesel generator set will be out of the neutral line at a frequency of 3 times during operation. Get the neutral current. Therefore, the neutral current of the generator must be measured under various load conditions that may occur during operation. In order to prevent the generator from overheating, the neutral current must not exceed 50% of the generator's rated current. If the neutral line power is too large, a neutral line reactor should be installed on the neutral line to limit it.

8) Electric parameters have to be adjusted

The frequency of dg set is generally adjusted to 51.5HZ (mechanical oil pump), the electronic speed control dg genset is generally adjusted to 50.0HZ, and the voltage of diesel engine generator set is 400V;

9) Gradually load

In order to run-in the whole machine, the first diesel engine generator set should be loaded gradually with load. The loading conditions are: 25%, 50%, 75%, and 100%. Each stage before 75% load should not be less than 30 minutes. According to the engine generator set type, it can run for a short time with 110% load to check the power of the diesel generator set;

10) Check the automatic protection functions of the diesel engine generator set: such as low oil pressure, high water temperature, overspeed, adjust or simulate the above three abnormal conditions, and check the protection and shutdown functions of the diesel generator set.

11) Check whether the diesel engine generator set has other functions.

| C Series 1250 kVA DG Set 50Hz Specification | |||

| Generator Model | BP-C1250 | Engine Model | Cummins KTA38-G9 (CCEC) |

| Standby Power | 1250kVA/1000kW | Prime Power | 1135kVA/908kW |

| Frequency | 50Hz | Rotational Speed | 1500rpm |

Engine Specification for C Series 1250 kVA DG Set 50Hz | |||

| Governor | Electronic | Weight | 3719KG |

| No. of Cylinders | 12 | Aspiration | Turbocharged & Aftercooled |

| Displacement | 38L | Fuel System | Direct Injection Cummins PT |

Hourly Fuel Consumption (100% Output Power) | 211L | Total System Oil Capacity | 135.1L |

| Power Range | 1090kW | Horse Power Range | 1460 |

Cummins KTA38 series engines are all with features as compact size, low fuel consumption, low vibration, low noise, low maintenance, high power output, high parts commonality & long service life, providing powered diesel gensets with great transient response, wide application, high economic efficiency & high reliability and meeting the medium or large power (prime or standby) demand on mining, hospitals, marines, military camps, factories, islands and other fields.

Dimension: 4410mm*2080mm*2190mm (Open type); 6050mm*2430mm*2580mm (20FT Containerized type)

Weight: 8156 kg (Open type); 10900 kg (20FT Containerized type)

The above are the specification for 1250 kva generator, and you will pay more attention to power genset alternators.

Everyone knows that the oil and fuel of a dg set must not be mixed. Because after mixing, it will not only affect the fuel combustion efficiency and reduce the working efficiency of the generator set. Long-term mixing may also cause the working failure of the generator set. Therefore, in daily life, it is necessary to master some troubleshooting methods caused by mixing, so as to deal with the failure of the engine generator set.

Injector: Remove the injector and test it on the high-pressure fuel pump test bench. If the opening pressure of the injector meets the requirements and the atomization is good, the injector is intact. Otherwise, it must be repaired or replaced .

Oil leakage at the front end of the fuel injection pump: Remove the inspection hole cover of the gear chamber cover. If a large amount of diesel is sprayed from behind the drive gear of the fuel injection pump, it can be concluded that the diesel engine has leaked into the oil pan from the fuel injection pump to mix with the oil.

Oil transfer pump: Remove the oil transfer pump, and add corresponding pressure to the oil inlet and outlet pipes on the oil pump test bench. If no diesel leakage is found, the oil transfer pump is intact.

Fuel injection pump: Remove the fuel injection pump and test it on the high-pressure fuel pump test bench. Finally, replace the fuel injection pump, and the fault can be resolved.

The above is what we have introduced to you about handling the problem of oil and fuel mixing in power genset. If you don’t know anything about this, please come to consult the official website of our Bidirection Power Technology Co., Ltd. will have a professional to explain to you.

There are many types of generator sets, and there are different types of generator sets according to different standards. 1. Divided by power source: diesel generator sets, gas generator sets, gasoline generator sets, wind generator sets, solar generator sets, hydroelectric generator sets, coal-fired generator sets, etc. 2. Electric energy mode: According to the converted electric energy mode, i...more