Ways to Reduce Noise of Diesel Generator Sets

Diesel generator set is a kind of mechatronic equipment converting the chemical energy of fuel into electric energy. Diesel generator sets are widely used and provide people with various conveniences. Meanwhile, the noise produced during the operation of the unit also directly affects people's health, daily work and daily life.

Therefore, to solve the above-mentioned noise issue is not only an important part of the application and development of dg sets, but also an important part of diesel generator suppliers & genset manufacturers' technical research. Here, we focus on the sources of noise from dg sets and ways to reduce them.

1. The production of noises

According to the working principle of diesel generator sets, the production of noises is very complicated. Analyzing from the reasons & sources, there are mainly six points as below:

a) Exhaust air noise

Exhaust air noise is a high-temperature & high-speed pulsating airflow noise, which is with the biggest energy and maximum parts of engine noises. It is much higher than the intake noise and the mechanical noise, and it is the main part of the total engine noises. Its fundamental frequency is the firing frequency of the engine. The main components of exhaust air noise are the following: low-frequency pulsating noise caused by periodic exhaust smoke, air column resonance noise in the exhaust pipe, Helmholtz resonance noise of the cylinder, noise from the process when high-speed air flows through the valve gap and tortuous pipes, eddy current noise & the regenerated noise generated by the pressure wave in the pipe of the exhaust system. The noise frequency increases significantly with the increase of airflow speed.

b) Mechanical noise

Mechanical noise is mainly caused by the vibration or mutual impact caused by the periodic changes of gas pressure and movement inertia force of the moving parts of the engine during operation. The most serious ones are the following: the noise of the lever mechanism, the noise of the valve mechanism, the noise of the transmission gear, the mechanical vibration and noise caused by the unbalanced inertial force. The strong mechanical vibration of the diesel generator set can be transmitted to various places outdoors through the foundation for a long distance, and then it will generate noise through the radiation of the ground. This kind of structure noise spreads far and attenuates few, and once formed, it is difficult to isolate.

c) Combustion noise

Combustion noise is structural vibration and noise generated by diesel fuel during combustion. The sound pressure level of combustion noise in the cylinder is very high. However, most parts of the engine structure have high rigidity, and their natural frequency is mostly in the middle and high frequency region. Due to the mismatch of the frequency response to the sound wave propagation, so the high peak cylinder pressure level under the low frequency range cannot be transmitted smoothly, while the cylinder pressure level under the middle & high frequency range is relatively easy to be transmitted.

d) Cooling fan and air ventilation noise

The fan noise of the unit is composed of eddy current noise and rotating noise. The rotating noise is caused by the periodic disturbance of the cutting air flow of the fan blade. The eddy current noise is caused by the airflow separating from the rotating blade section. Air ventilation noise, airflow noise, fan noise, and mechanical noise are all transmitted through the air ventilation passage.

e) Inlet air noise

Diesel generator sets require sufficient fresh air supply during normal operation. On the one hand, it ensures the normal operation of the engine, on the other hand, it creates good heat dissipation conditions for the unit. Otherwise, the unit cannot guarantee its performance. The air inlet system of the unit basically includes the air inlet channel and the air intake system of the engine itself. The air inlet channel of the unit must enable the fresh air to enter the engine room smoothly. At the same time, the mechanical noise and airflow noise of the unit can also be transmitted to the engine room through this air inlet channel outside.

f) Alternator noise

Alternator noise includes electromagnetic noise caused by magnetic field pulsation between stator and rotor, and mechanical noise caused by rolling bearing rotation.

2. Ways to reduce noise

According to the above noise analysis, the following two methods are generally used for reducing the noises of dg sets:

1) Make silent type unit (silent dg set)

Install soundproof foam in the canopy of the unit, rationally arrange the exhaust duct and silencer and install shock absorbers between the body and the base

2) Make noise reduction treatment in a dg set room

Compare to a dg set unit, there are much more space for a room to deal with the causes of the above noise. The specific methods are as follows:

a. To reduce noise from air intake and exhaust

The air intake and exhaust channels of the dg set room are respectively made of soundproof walls, and sound-absorbing films are installed in the air intake and exhaust channels. There is a certain distance in the channel for buffering, so that the intensity of the sound source radiated from the dg set room can be reduced.

b. To control mechanical noise

Install sound-absorbing and sound insulation materials with high sound absorption coefficient on the top and surrounding walls of the dg set room, which are mainly used to eliminate indoor reverberation and reduce the sound energy density and reflection intensity in the dg set room. In order to prevent noise from radiating outward through the gate, set fire-proof iron gates.

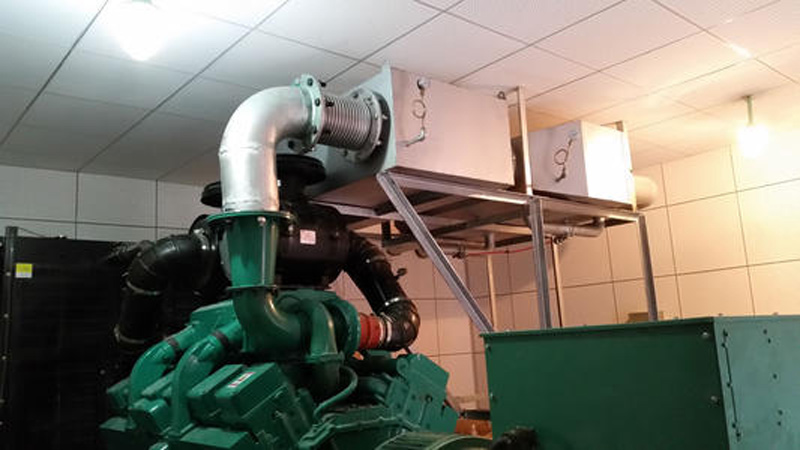

c. To control exhaust smoke noise

The smoke exhaust system is equipped with a special second-level muffler on the basis of the original first-level muffler, which can ensure the effective control of the smoke and noise of the unit. If the length of the exhaust pipe exceeds 10 meters, the pipe diameter must be increased to reduce the exhaust back pressure of the generator set. The above processing can improve the noise and back pressure. Through noise reduction processing, the noise of the generator set in the dg set room can meet the requirements of the user outdoors. Noise reduction in a dg set room generally requires sufficient space in the dg set room. If users cannot provide a dg set room with a sufficient space, the noise reduction effect will be affected. Therefore, air inlet channels, exhaust channels, and operating space for staff must be provided in the dg set room.

Note: After noise reduction, in order to correct the actual power of diesel generator sets (the power of the diesel generator will decrease after noise reduction treatment), diesel generator sets need to be run on-load. It is helpful to reduce and avoid accidents and improve safety.