9 Tips for Proper Diesel Generator Maintenance

Like other common mechanical equipment, diesel generator sets also require daily repairs and maintenance. The following 9 tips can help you to make the service life of a dg set longer and make the operation process smoother.

1. Routine General Inspection

During the running of the diesel generator, any potential leaks that can cause dangerous accidents require monitoring, including the monitoring for exhaust system, fuel system, DC electrical system and alternator. The operation of a dg set unit causes vibration, which is likely to cause loose or even falling off of bolts or other parts in certain area of the body as time goes on. It is necessary to check regularly whether there is any loose or falling off of above mentioned.

2. Inspect Lubrication System

The lubrication system of a generator set is very important. It plays the role of lubricating, cooling and cleaning the moving parts of the dg set, and at the same time, it also plays a role of sealing to prevent the surface of some parts from rusting. Before starting the engine, it is usually necessary to use the dipstick to check the oil level of the engine oil. The oil level should be as close as possible to the full scale. The oil and filter need to be replaced regularly. 500 running hours is the recommended standard maintenance and oil change time, but some special occasions may require shorter or longer maintenance time. If you need to add or replace oil, you should add oil of the same quality and brand as much as possible. It is best to buy lubricants that meet OEM specifications.

3. Inspect Cooling System

Check the coolant level from time to time when the unit is not running (when engine is cool). Remove the radiator cap when the engine is cooling, and check whether the radiator is full. The coolant can be water, antifreeze or other coolant additives, or a mixture of them. Check daily for obstacles on the outside of the radiator, and remove all dirt or foreign objects to avoid damage to the heat sink.

4. Inspect Fuel System

Diesel is subject to contamination and corrosion within a period of one year, and therefore regular generator set exercise is highly recommended to use up stored fuel before it degrades. The fuel filters should be drained at the designated intervals due to the water vapor that accumulates and condenses in the fuel tank. Regular testing and fuel polishing may be required if the fuel is not used and replaced in three to six months. Preventive maintenance should include a regular general inspection that includes checking the coolant level, oil level, fuel system, and starting system. The charge-air cooler piping and hoses should be inspected regularly for leaks, holes, cracks, dirt and debris that may be blocking the fins or loose connections. Replace fuel filters & fuel water separator if necessary during maintenance.

5. Inspect Batteries

Weak or undercharged starting batteries are a common cause of standby power system failures. The battery must be kept fully charged and well-maintained to avoid dwindling by regular testing and inspection to know the current status of the battery and avoid any start-up hitches of the generator. They must also be cleaned; and the specific gravity and electrolyte levels of the battery checked frequently. Check if the terminals are oxidized or loose.

6. Routine Engine Exercise

Regular exercising keeps the engine parts lubricated and thwart oxidation of electrical contacts, uses up fuel before it deteriorates, and helps to provide reliable engine starting. Engine exercise is recommended to be executed at least once a month for a minimum of 30 minutes loaded to no less than one-third of the nameplate rating.

7. Inspect Exhaust System

In case there are any leaks along the exhaust pipe line which usually occurs at the connection points, the welds and the gaskets, which should be repaired immediately by a qualified technician. Always make sure your units are serviced, especially 24 hrs before using your generators. For standby generators, you need to have your units serviced 150hrs on average. However, if the generator is used constantly the hours go up much quicker and in more regular intervals.

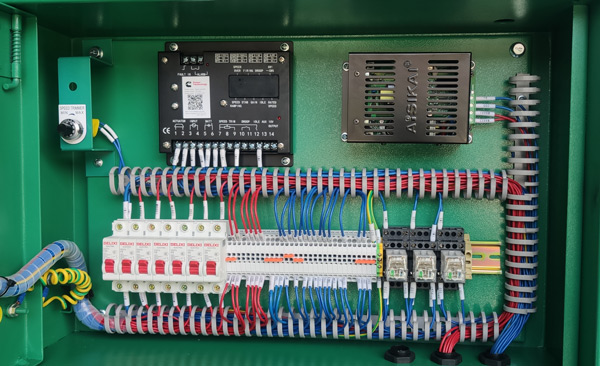

8. Inspect Electrical Wiring

Check whether the electrical wiring of each part of the whole generator set is loose or falling off, such as the wiring inside the control cabinet, the load wiring at terminal ends, some wiring with various parts of the engine body, emergency stop devices, etc.

9. Keep the Diesel Generator Clean

The diesel generator should be kept clean. Oil drips and other issues are easy to spot and take care of when the engine is nice and clean. Visual inspection can guarantee that hoses and belts are in good condition. Frequent checks can keep wasps and other nuisances from nesting in your equipment. The more a generator is used and relied on, the more it needs to be taken care of. However, a generator set that is rarely used might not need a lot of care.